Think of manufacturing units that predict disruptions early and optimize output in real-time, redefining how factories operate. Based on research carried out by McKinsey, AI in manufacturing and supply chains can generate $1.2 – $2 trillion annually, driven by gains in output, quality, and operational efficiency.

This article focuses on how adoption of AI in manufacturing is revolutionizing the industry, from predictive maintenance to optimizing supply chain operations.

Discover use cases and real examples that show how businesses are reducing downtime, streamlining operations, and staying competitive.

How AI in Manufacturing Is Transforming the Industry Framework

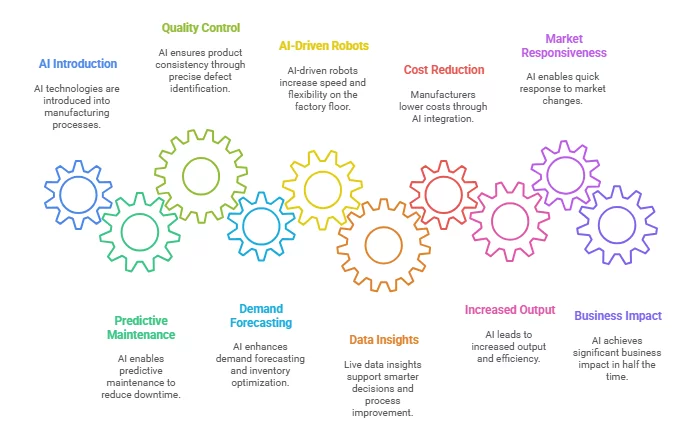

AI has introduced a revolution in the manufacturing industry, by bringing intelligence, automation, and efficiency throughout the workflow. The transformation is impacting the manufacturing industry by enabling predictive maintenance, reducing downtime, and extending equipment life. Quality control driven by AI ensures product consistency, as it identifies defects with precision.

AI enhances demand forecasting and inventory optimization in supply chain management. AI-driven robots boost speed and flexibility on the factory floor. Live data insights support smarter decisions and consistent improvement of processes. Seamless integration of these technologies enables manufacturers to lower their costs, increase output, and respond quickly to market changes, making AI and ML services a key driver in transforming the industry landscape for prolonged success.

In a collaborative study conducted by McKinsey and MIT MIMO, it was revealed that manufacturers that fully embrace AI achieve four times the business impact in half the time. These companies harness the power of AI across operations to improve efficiency, quality, and innovation. This joint study highlights that with strong organizational foundations, like capable teams, sound governance, and data, AI drives key shifts across operations and strategy.

Use Case Scenarios and Practical Examples of AI in Manufacturing

AI is no longer just a futuristic concept now. It is reshaping the way manufacturing processes are managed and executed. It streamlines operations across industries, ultimately resulting in lowering expenses and enhancing product standards. Curious how this transformation appears in real-world scenarios? Well, read on to explore.

Let us dive into use cases along with examples of AI in manufacturing:

Predictive Maintenance

Smart maintenance strategies leverage AI and machine learning, helping manufacturers monitor machine equipment in real-time and detect issues before any damage is done. Unlike the traditional routine of scheduled checks, the system alerts the team only when maintenance is actually needed.

Besides, with this proactive approach, the occurrence of disruptions trims, leading to reduced repair costs and improved asset longevity. By utilizing predictive insights, manufacturers boost operational efficiency and keep production running smoothly without costly interruptions.

Real-life Applications: Siemens

For instance, Siemens, a global tech company, is using AI-powered predictive maintenance in its Amberg plant in Germany, for monitoring critical equipment. This intelligent system makes use of IoT sensors and machine learning algorithms to identify early warning signs of potential failures. Timely precaution eliminates the occurrence of breakdowns through prompt interventions.

Consequently, the organization has achieved fewer disruptions, prolonged machine performance, and smoother, uninterrupted manufacturing operations.

Quality Control and Defect Detection

Quality control powered by AI uses computer vision and machine learning to inspect products during manufacturing. The system detects defects, deviations, and quality issues more accurately compared to manual checks. The approach prevents faulty products from reaching customers, by analyzing data in real-time and flagging quality issues early.

Through automating quality checks with AI, manufacturers improve consistency, reduce waste, and ensure high standards. Not only does this enhance product quality but also enhances both operational efficiency and customer satisfaction.

Real-life Applications: BMW

BMW harnesses the power of AI in image recognition systems to analyze vehicle components on its production lines. They employ high-resolution cameras along with AI algorithms to scan even the tiniest defects in the vehicle components. The HD cameras are so precise that they even detect paint inconsistencies or surface scratches.

Additionally, automated technology ensures high precision in quality control, reduces manual errors, and speeds up inspection time. Thus, AI adoption in manufacturing allows BMW to deliver consistent product quality, reduced expenses, and improved customer experience through this approach.

Demand Forecasting and Inventory Optimization

AI-powered forecasting models analyze past sales data and process market indicators to anticipate demand. Such predictions enable manufacturers to fine-tune inventory, cut carrying costs, and synchronize production schedules. Furthermore, it reduces stockouts, boosting cash flow, and customer satisfaction.

Real-life Applications: Unilever

With AI-driven demand forecasting, Unilever optimizes its global inventory. It employs machine learning algorithms to analyze historical data, seasonal patterns, and external factors such as weather and market shifts. AI implementation enables Unilver to make accurate predictions regarding product demand and adjust inventory levels accordingly.

With the help of AI, the company has lowered out-of-stock incidents, minimized overproduction, and improved on-time deliveries. Ultimately, it has enhanced both operational efficiency and customer satisfaction.

Supply Chain Optimization

AI has a pivotal role to play in optimizing the supply chain in manufacturing. The system helps forecast demand, analyze market trends, and manage inventory efficiently. AI technology aids in detecting disruptions early, recommends better logistics routes, and ensures timely deliveries. Moreover, improved visibility and better planning prevent delays, minimize costs, and maintain a flexible, demand-driven supply chain that adapts quickly to market trends.

Real-life Applications: DHL

DHL, the global leader in the logistics industry, is harnessing AI and advanced analytics to enhance its global supply chain resilience. The company is using predictive algorithms to predict delivery delays, optimize routes, and manage warehouse workloads effectively.

Moreover, AI enables DHL to perform demand forecasting, helping balance inventory levels and reduce transit times. So, that’s how DHL carries out quicker deliveries, achieves lower operational costs, and finally increases customer satisfaction.

Robotics and Automation

AI integration in robotics and automation in manufacturing enables machines to adapt and make effective decisions. This ensures more intelligent and flexible systems on the floor. These AI-powered robots can manage complex tasks with precision. It makes the system too smart that it rapidly adapts to changes and collaborates with humans effectively. Such automatic operation improves productivity, reduces errors, and lowers operational expenses, thereby creating smarter, more efficient production lines that respond quickly to real-time demands.

Real-life Applications: Audi

Audi has AI-powered robots that have computer vision systems, which automate quality control. Robotic arms driven by AI perform scanning of car bodies for paint defects. Automated systems are so precise that they are capable of spotting minuscule scratches, bubbles, or dust particles on the car bodies, that are not visible to the human eye. It ensures flawless finishes and cuts down inspection time from minutes to seconds.

Process Optimization

AI does operational streamlining in manufacturing by crunching real-time data from factory sensors and machinery. The technology spots roadblocks, anticipates machine breakdowns for predictive maintenance, and catches quality problems fast. This leads to quick tweaks to production, better resource use, less waste, and ultimately, higher efficiency and product quality.

Real-life Applications: Siemens

With the help of AI and IoT sensors, Siemens, a tech giant, performs predictive maintenance. AI analyzes real-time machine data like vibration, and temperature to detect anomalies and predict equipment failures before they occur. It enables proactive repairs, minimizing unplanned downtime, and optimizing maintenance schedules. Apart from that, task automation extends equipment lifespan, boosting overall factory efficiency and cost-effectiveness.

Product Design and Innovation

AI accelerates product development by evaluating customer data, analyzing market changes, and performance feedback. Now designers can test prototypes rapidly, resulting in lower development cycles. Innovative ideas and improvements are suggested through machine learning, enabling the creation of smarter, more efficient products. This leads to quicker time-to-market and products that better meet customer needs.

Real-life Applications: General Motors (GM)

The world’s largest Motorcycle manufacturer, GM, employs AI-driven generative design to fast-track product development. The company feeds its design requirements into AI software to generate various innovative part designs in no time. Utilizing AI for ideation purposes led to the creation of lighter and stronger components, such as redesigned seatbelt brackets, improving both fuel efficiency and safety without compromising performance.

Worker Safety Monitoring

AI ensures worker safety by using computer vision and sensors to monitor environments in real-time. The system eliminates the risks of hazards through early detection and enforces safety protocols and alerts. By timely prevention, possibilities of accidents are avoided. Also, this ensures compliance, thereby creating a safer, more responsive workplace for employees on the factory floor.

Real-life Applications: Honeywell

A multinational conglomerate corporation, Honeywell, benefits from AI-based computer vision and wearable sensors, as they enhance worker safety in industrial environments. They have implemented smart systems for tracking workers’ movements, identifying unsafe behaviors like zone violations or improper lifting, and sending real-time alerts. Continuous monitoring has led to fewer workplace incidents and better adherence to safety standards across manufacturing facilities.

Natural Language Processing (NLP) for Maintenance and Support

With AI-powered NLP, technicians can access maintenance systems by interacting and using voice or text commands. AI-driven NLP streamlines troubleshooting by interpreting queries and retrieving relevant documentation or repair steps. This leads to reduced downtime, speeding up support.

Apart from that, it also makes technical knowledge more accessible, especially for those workers, who are less experienced, ultimately enhancing overall maintenance efficiency and responsiveness.

Real-life Applications: General Electric (GE)

General Electric, a multi-national conglomerate, leverages AI-driven NLP in its Predix platform, empowering maintenance technicians to interact with machines through natural language. Through voice or text inputs, workers can instantly access equipment manuals, diagnostic data, or troubleshooting instructions. Such voice-driven assistance reduces troubleshooting time, prevents system outages, and equips technicians with real-time, context-aware information across the shop floor.

AI in manufacturing: The Road Ahead

The influence of AI in manufacturing will continue to play an increasingly critical role in the coming years. With more companies investing in digital transformation, AI will drive operations at every level – from day-to-day operations to strategic planning. Still, achieving success requires building a strong data infrastructure, retraining the workforce, and ensuring ethical AI practices.

“AI is the defining technology of our times. It’s already transforming every industry, including manufacturing, and empowering companies to drive innovation and operational excellence.”

Satya Nadella – CEO of Microsoft

Ultimately, AI is not just a technological upgrade, instead redefines the way manufacturers function, compete, and scale. Businesses that adopt it will be positioned to respond to shifting demands and influence industrial progress.

How Intelegain’s Custom AI Fuels High Performance

Intelegain empowers businesses to achieve peak performance with custom-built AI and ML solutions tailored to their specific requirements. From Conversational AI solutions ChatBot that delivers seamless customer interactions, Generative AI for smarter content creation, or Predictive systems that identify future trends and behavior, Intelegain drives results that matter.

Powered by agile methods and in-depth industry knowledge, it doesn’t just implement AI, it transforms it into A results-focused engine crafted to match your business needs.

Ready to unlock peak performance with custom AI?

Contact Intelegain today and turn innovation into your competitive edge. Let’s build smarter, faster, and future-ready solutions together.